Atrex Energy has worked on research and development of a commercially viable power generator utilizing Solid Oxide Fuel Cells (SOFC) since 2000. The company has made substantial progress in improving the technology over this timeframe:

Increased the output per fuel cell tube 120-fold

Developed SOFC designs with peak output over 10 kW; the first working SOFC generated a mere 20 watts of power

Tripled power density

Developed 18 patented innovations

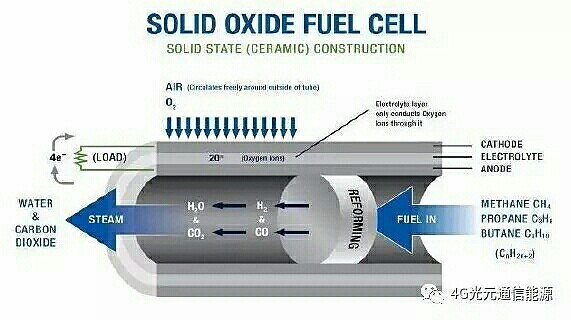

SOFC technology uses low-cost, stable ceramics as its electrolyte layer; the use of ceramics and high temperatures eliminate the need for expensive metal catalysts such platinum which are used in PEM fuel cells. The high temperatures (600°C to 800°C) used in the Atrex Energy design allows conventional hydrocarbon fuels such as natural gas, propane and lpg to be used directly without requiring an external reforming process. There is no need to transport or store hydrogen, avoiding another layer of complexity.

While most SOFCs use a planar design—thin sheets of material forming the layers—Atrex developed a tubular design in which the layers are added to a cylindrical base.

Atrex forms its tubular SOFCs by by hydraulically pressing ceramic anode material into tubes and coating the tubes with an electrolyte layer and then a cathode layer; the anode is on the inside of the tube, while the cathode is on the outside. The fuel is injected inside the tube; air is on the outside.

With the Atrex Energy SOFC design, reforming of the fuel takes place inside the tubes using commercially available fuels with hydrogen-rich content, such as natural gas and propane. By combining a small amount of air with the fuel inside the tubes, along with the inherent temperature of the Atrex Energy SOFC process, the fuel is automatically reformed to produce the needed hydrogen as well as carbon

The zirconium oxide electrolyte allows only oxygen ions to pass through, carrying electrons from the cathode to the anode. This design provides a very strong structure and makes it relatively easy to seal, preventing the air and fuel from mixing.

Atrex Energy assembles the tubes into a bundle or stack. This creates a fuel cell system that can currently handle loads from 100 watts up to 4.5kW. The net result is a power generator that produces clean electricity more efficiently than other power generation technologies.

The only by-products of the Atrex Energy SOFC design are water vapor, heat and low levels of carbon dioxide. Because operation is below the high temperature of internal combustion engines or turbines, fuel cells have nearly undetectable levels of NOx. The desulfurizing fuel filters along with the high efficiency of Atrex Energy’s fuel cell reduces the sulfur oxide (SOx) emissions to negligible levels. Efficiency is further enhanced when the heat is recovered for heating, hot water and processing purposes.

The patented tubular design eliminates catastrophic damage due to temperature gradients. Temperature gradients occur during the normal thermal cycling that takes place during start-up, shut down and load changes. This cycling, over the lifetime of the unit, introduces stresses that could eventually manifest into cracks and ultimately failure.

The small radius geometry of Atrex Energy’s tubes, their inherent strength, the strong seal at one end and the operation under low pressure combine to minimize temperature gradients. This allows the tubes to easily tolerate thermal cycling. In addition, Atrex Energy’s tubular design is much more tolerant to the stresses from internal reforming, the company said.

阿特雷克斯能源公司(Atrex Energy)自2000年以来一直致力于研发利用固体氧化物燃料电池(SOFC)的商业可行的发电机组。该公司在此时间段内,在改进技术方面取得了实质性进展:

将每个燃料电池管的输出增加到120倍

开发的SOFC设计,峰值输出超过10 kW;

第一个工作的SOFC产生的功率仅为20瓦

三倍的功率密度

开发了18项专利创新

SOFC技术使用低成本且稳定的陶瓷作为其电解质层;陶瓷和高温的使用消除了在PEM燃料电池中使用昂贵的金属催化剂铂的需要。 Atrex Energy设计中使用的高温(600°C至800°C)可以直接使用常规碳氢化合物燃料,如天然气,丙烷和LPG,无需外部重整过程。没有必要运输或储存氢气,避免了另一层复杂性。

虽然大多数SOFC使用平面设计薄片材料 - Atrex开发了一种管状设计,其中将陶瓷薄片加入到圆柱形基座中。

Atrex通过将陶瓷阳极材料液压压入管中并用电解质层和阴极层涂覆管来形成其管状SOFC,阳极位于管的内侧,阴极位于外侧。燃料被注入管内;空气在外面。

使用Atrex Energy SOFC设计,燃料的重整在管内使用具有富氢含量的市售燃料(如天然气和丙烷)进行。通过将少量空气与管内的燃料结合,以及Atrex能量SOFC工艺的固有温度,燃料自动重整以产生所需的氢气以及碳

Altrex

氧化锆电解质仅允许氧离子通过,将电子从阴极传送到阳极。这种设计提供了非常坚固的结构,使其相对容易密封,防止空气和燃料混合。

Atrex Energy将管子组装成束或电堆。这创建了一个燃料电池系统,目前可以处理100瓦特至4.5kW的负载。最终的结果是发电机比其他发电技术更有效地产生清洁电力。

Atrex Energy SOFC设计的唯一副产品是水蒸汽,热和二氧化碳水平低。由于操作低于内燃机或涡轮机的高温,所以燃料电池几乎不可检测的NOx水平。脱硫燃料过滤器以及Atrex Energy燃料电池的高效率将硫氧化物(SOx)排放减少到可忽略的水平。当回收热量用于加热水和加工目的时,效率进一步提高。

专利的管状设计消除了由于温度梯度引起的灾难性损坏。在启动,关闭和负载变化期间发生的正常热循环过程中会发生温度梯度。在这个单位的整个过程里,这种循环最终可能表现为裂缝和失败。

Atrex Energy管的小半径几何形状,它们的固有强度,一端的强密封和低压下的操作结合起来使温度梯度最小化。这允许管很容易耐受热循环。此外,Atrex Energy的管状设计更加适应内部气体重整带来的压力。