新闻稿

2023年10月13日

柏林

最新成功的一系列测试为碳中和发电和工业脱碳提供了决定性的前景。

HYFLEXPOWER项目安装在法国Saillat-sur-Vienne的纸包装世界领导者Smurfit Kappa的现场,包括生产、储存和再电气化100%可再生氢气。氢气由现场1兆瓦的电解槽生产,然后储存在近一吨的储罐中,用于为西门子能源SGT-400工业燃气轮机提供动力。

HYFLEXPOWER项目表明,氢气可以用作灵活的储能介质,也可以将现有的燃气动力涡轮机转换为使用可再生氢气运行。因此,它是加速最能源密集型行业脱碳的真正驱动力。

2022年,最初的一系列测试使工业燃气轮机能够以30%的氢含量运行,并与天然气混合。现在,动力到氢到动力的演示器已经证明,采用干式低排放技术的最先进的涡轮机可以使用高达100%的氢气以及天然气和介于两者之间的任何混合物提供燃料。

从演示者到市场

HYFLEXPOWER财团包括西门子能源、ENGIE通过其子公司ENGIE Solutions、Centrax、Arttic、德国航空航天中心(DLR)和四所欧洲大学。

基于HYFLEXPOWER演示者的承诺,计划扩大财团,以包括更多成员。在测试了HYFLEXPOWER的电力生产后,现在的目标是将其运营扩展到工业热能生产和其他操作模式。它还计划探索扩大脱碳发电规模和商业化的方法。

欧盟委员会支持的模范多伙伴项目

HYFLEXPOWER从欧盟的地平线2020研究和创新框架计划获得了大量资金。*

作为财团的牵头人,西门子能源公司为氢气生产提供了电解槽,并开发了氢气涡轮机。ENGIE为演示者建立了氢气生产、储存和供应。Centrax负责软件包升级,以确保氢燃料的安全运行。德国航空航天中心(DLR)和隆德大学(瑞典)、杜伊斯堡-埃森大学(德国)和伦敦大学学院(英国)为氢涡轮机技术开发做出了贡献。Arttic支持运营项目管理,而雅典(希腊)的NTUA对该概念进行了经济、环境和社会分析。

“从HYFLEXPOWER项目中获得的知识和经验,我们安装了第一台100%氢气的燃气轮机,这将有助于我们继续为基于氢气的未来发展我们的整个燃气轮机车队。一个地点的电解、储存和氢转换之间的相互作用已经令人印象深刻地证明了,现在这是一个扩大结果的问题,”西门子能源执行董事会成员卡里姆·阿明说。

“在ENGIE,我们为这个世界第一感到非常自豪。HYFLEXPOWER项目之所以引人注目,原因有很多:它促成了几个欧洲合作伙伴之间的卓越合作,它测试了前瞻性技术,以及它为在最难脱碳的工业部门使用可再生氢带来了广阔的前景。ENGIE负责能源解决方案的执行副总裁弗兰克·拉克鲁瓦说:“我们期待与我们的合作伙伴一起继续为脱碳行业的未来开展这项决定性的工作。”

“我们感到自豪的是,我们的Saillat造纸厂一直是这个项目的东道主,因为试验新的和新兴技术,如氢气,符合我们的脱碳战略和更好的星球2050之旅。今天的公告是一个伟大的里程碑,让我们处于有利地位,”Smurfit Kappa首席可持续发展官Garrett Quinn说。

*该项目已根据第884229号赠款协议获得欧洲地平线2020创新和研究计划的资助

HYFLEXPOWER consortium successfully operates a gas turbine with 100 percent renewable hydrogen, a world first

网页链接{Press release}October 13, 2023

Berlin

Latest successful series of tests offer a decisive outlook for carbon-neutral power generation and the decarbonization of industry.

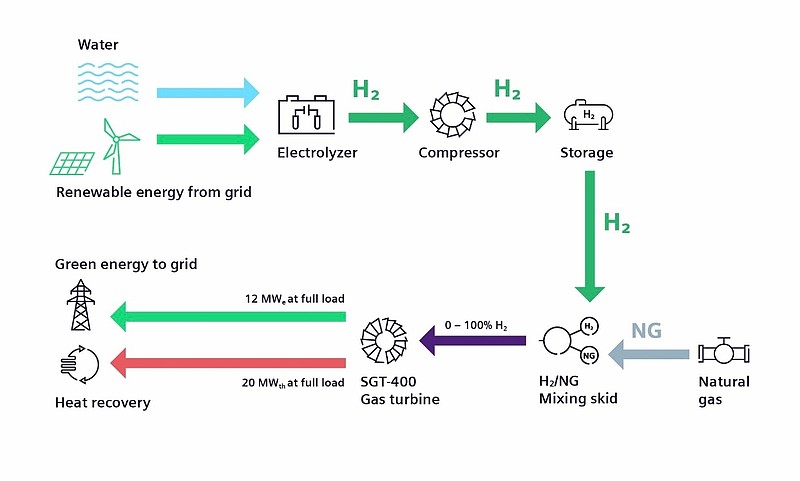

Installed on the site of Smurfit Kappa, world leader in paper packaging, at Saillat-sur-Vienne in France, the HYFLEXPOWER project consists in producing, storing and re-electrification of 100 percent renewable hydrogen. The hydrogen is produced by an 1MW electrolyzer on-site, and then stored in an almost one-ton tank and used to power a Siemens Energy SGT-400 industrial gas turbine.

The HYFLEXPOWER project demonstrates that hydrogen can be used as a flexible energy storage medium, and that it’s also possible to convert an existing gas-fired power turbine to operate using renewable hydrogen. Thus it is a real driver for accelerating the decarbonization of the most energy-intensive industries.

In 2022, an initial series of tests enabled the industrial gas turbine to operate with a 30 percent hydrogen content, mixed with natural gas. Now the power-to-hydrogen-to-power demonstrator has proven that state-of-the-art turbines with dry low emissions technology can be fueled with up to 100% hydrogen as well as with natural gas and any blends in between.

From demonstrator to market

The HYFLEXPOWER consortium includes Siemens Energy, ENGIE via its subsidiary ENGIE Solutions, Centrax, Arttic, the German Aerospace Center (DLR), and four European universities.

Building on the promise of the HYFLEXPOWER demonstrator, it is planned to expand the consortium to include additional members. Having tested HYFLEXPOWER for electricity production, the goal is now to extend its operation to industrial heat production and additional operational modes. It is also planned to explore ways of scaling up and commercializing decarbonized electricity generation.

Exemplary multi-partner project supported by the European Commission

HYFLEXPOWER has received substantial funding from the European Union’s Horizon 2020 Framework Programme for Research and Innovation.*

As the consortium lead, Siemens Energy supplied the electrolyzer for hydrogen production and developed the hydrogen gas turbine. ENGIE built the hydrogen production, storage and supply for the demonstrator. Centrax were responsible for the package upgrade to ensure safe operation with hydrogen fuel. The German Aerospace Center (DLR) and the Universities of Lund (Sweden), Duisburg-Essen (Germany), and University College London (UK) contributed to the hydrogen turbine technology development. Arttic supported the operational project management, while NTUA in Athens (Greece) carried out economic, environmental, and social analysis of the concept.

"The knowledge and experience gained from the HYFLEXPOWER project where we installed the 1st gas turbine to run on 100 percent hydrogen will help us to continue develop our entire gas turbine fleet for a hydrogen-based future. The interaction between electrolysis, storage, and hydrogen conversion at one site has been impressively demonstrated, and now it's a matter of scaling the results," says Karim Amin, Member of the Executive Board of Siemens Energy.

"At ENGIE, we are very proud of this world first. The HYFLEXPOWER project is remarkable for many reasons: for the exceptional collaboration it has enabled between several European partners, for the forward-looking technologies it has tested, and for the promising prospects it opens up for the use of renewable hydrogen in the industrial sectors most difficult to decarbonize. We look forward to continuing this decisive work for the future of decarbonized industry with our partners,' says Frank Lacroix, ENGIE Executive Vice President in charge of Energy Solutions.

“We’re proud that our Saillat paper mill has been the host for this project because trialing new and emerging technology, such as hydrogen, aligns with our decarbonization strategy and Better Planet 2050 journey. Today’s announcement is a great milestone that puts us in good stead,” says Garrett Quinn, Chief Sustainability Officer at Smurfit Kappa.

* This project has received funding from the European Horizon 2020 innovation and research program under grant agreement n°884229